VELUX Commercial offers a variety of architectural paint color options and finishes, all compliant with AAMA specifications. But it is our in-house powder coat finishes that really shine! The most environmentally friendly options available on the market today, VELUX Commercial powder coat finishes use no solvents, eliminating VOCs and allowing for safer disposal processes without using chrome. Powder coat finish options require less energy consumption with multiple color options and are protected under longer warranties than liquid and anodized finishes. Copper cladding is also available.

Download Information Sheet

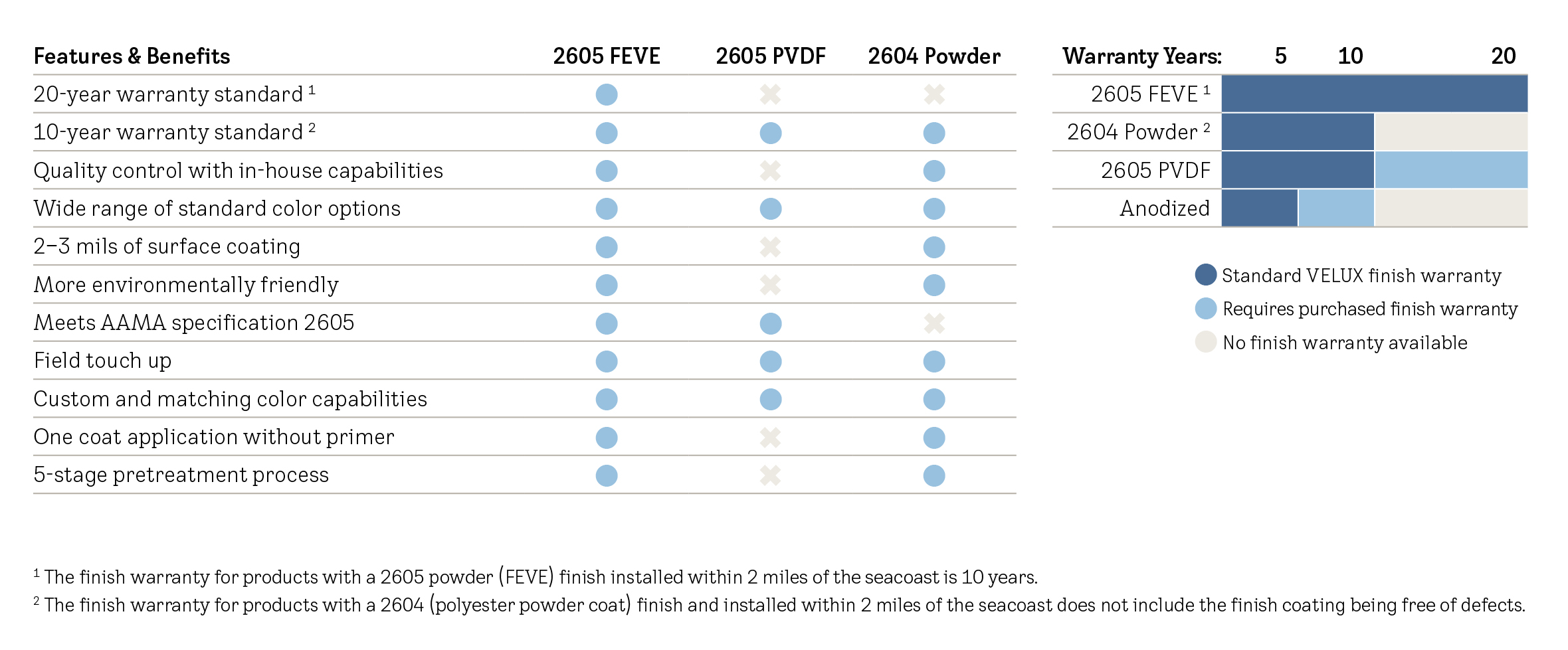

AAMA 2605 FEVE Powder Coat – 20-Year Warranty

Fluoroethylene Vinyl Ether (FEVE) powder coat finish meeting AAMA 2605 requirements

Designed to withstand the elements and airborne pollutants, our fluorpolymer 2605 Powder Finish is resistant to chipping, cracking, and peeling to keep your finish looking new without staining or discoloration. 2605 Powder Finish has a proven performance of excellent long-term appearance and requires minimal maintenance. It is easy to keep clean, and the lack of solvents used in its powder coating process makes it more environmentally friendly than PVDF and anodized finishes. 2605 Powder Finish comes complete with a 20-year finish warranty.*

Gloss powder coat finish formulated with durable fluoropolymer resins and solar-reflective pigments:

AAMA 2604 Powder Coat Finish – 10-Year Warranty

Polyester powder coat finish meeting AAMA 2604 requirements

Formulated with super durable polyester resins and solar-reflective pigments, 2604 Powder Finish provides excellent gloss retention and long-term resistance against the weather. 2604 Powder Finish is available in a variety of colors, including ones that use mica pigments to mimic anodized finishes while delivering a smooth, ultra-matte finish. In other words, you can have that anodized look at a more cost-effective rate without the potential problems that come with anodizing, like surface imperfections showing through or difficult touch-ups. It is covered by a 10-year finish warranty.**

Gloss powder coat finish formulated with durable polyester resins and solar-reflective pigments:

Anodized metal appearance, ultra-matte smooth powder coat finish:

| The colors shown are approximate and are intended as a guide only. Upon request, VELUX will supply an actual color chip or chips of the colors you have specified. Custom and matching 2604 Powder colors available. ** 2604 Powder Finish not warrantied against peeling on products installed within two miles of the seacoast. |

AAMA 2605 PVDF Finish – 10-Year Warranty

Polyvinylidene Fluoride (PVDF) liquid fluoropolymer finish meeting AAMA 2605 requirements

A highly inert and stable fluoropolymer resin, PVDF provides excellent resistance to metal weathering over time. 2605 PVDF Finish utilizes PVDF to resist weathering, chalking, fading, and UV rays, making it ideal when a durable coating is needed. 2605 PVDF Finish is available with a 10-year finish warranty with the ability to purchase an extended finish warranty of up to 20 years.

Anodized Finish – 5-Year Warranty

Anodized finish meeting AAMA 611 Class I requirements VELUX Commercial also offers a variety of anodized finishes. Anodizing is the process of electrochemically controlling, accelerating, and enhancing oxidation of an aluminum substrate. This produces an oxide film that is uniform, durable, and protects the rest of the aluminum substrate from deterioration. Available in multiple colors, VELUX Commercial anodized finishes come with a 5-year finish warranty with the ability to purchase an extended finish warranty of up to 10 years.

| |

| The colors shown are approximate and are intended as a guide only. Upon request, VELUX will supply an actual color chip or chips of the colors you have specified. |

AAMA Compliant

VELUX Commercial finishes are 100% compliant of all AAMA specifications.

| 2605 FEVE, 2605 PVDF | 2604 Powder | Anodized | |

| AAMA Specification | AAMA 2605 | AAMA 2604 | AAMA 611 – Class I |

| South Florida Weathering | |||

| Color retention | 10 yrs: Fade = 5 Delta E | 5 yrs: Fade = 5 Delta E | 10 yrs: Fade = 5 Delta E |

| Chalk resistance | 10 yrs: Chalk = 8 | 5 yrs: Chalk = 8 | N/A |

| Gloss retention | 10 yrs: 50% retention | 5 yrs: 30% retention | 15 unit variation |

| Erosion resistance | 10 yrs: 10% loss | 5 yrs: 10% loss | No specification |

| Dry film thickness | 1.2 mils minimum | 1.2 mils minimum | 0.7 mils minimum |

| Pretreatment System | Chrome or Chrome Free | Chrome or Chrome Free | No specification |

| Accelerated Testing | |||

| Salt Spray | 4,000 hours | 3,000 hours | 3,000 hours |

| Humidity | 4,000 hours | 3,000 hours | No specification |

Kynar 500® is a registered trademark of Arkema Inc.